| |||||||||

|

|

| Infrastructure |

|

Immersive Design Lab

The Immersive Design Lab (IDL) is an interdisciplinary laboratory at ETH Zurich for future design, architecture and engineering. Gramazio Kohler Research initiated and implemented the IDL in collaboration with experts from the fields of extended reality and acoustics. The lab is located in the Hoenggerberg Campus of ETH Zurich, in the HIT F22 and will be fully operational from May 2021 on.

Robotic Fabrication Laboratory The Robotic Fabrication Laboratory (RFL) was initiated and developed by Gramazio Kohler Research. It comprises a multi-robotic system based on an overhead gantry system. Four industrial robot arms of the type ABB IRB 4600 move on a linear axis and can cooperate in an area up to a volume of 45 x 17 x 6 meters. The RFL’s flexible and extendable configuration allows for a broad scope of different applications at full scale. The RFL is designed to facilitate human-machine cooperation while at the same time allowing for fully automated factory-based digital fabrication processes. With the opening of the new Arch_Tec_Lab building in autumn 2017 the RFL was put into operation.

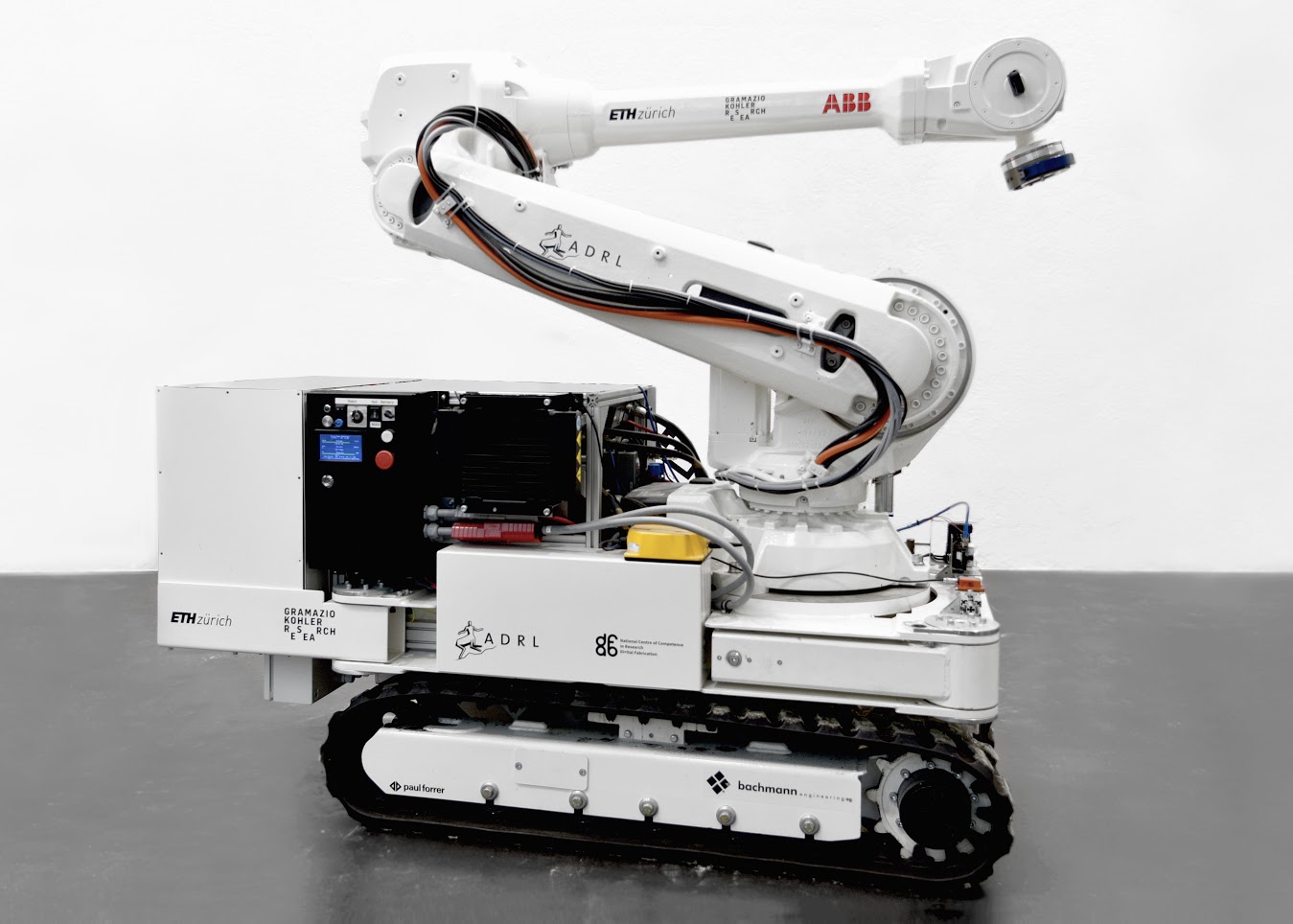

In situ Fabricator The onboard sensing and computation system of the robot allows for construction without any external measurement devices. It orients itself relative to the foundation of the wall, which is installed prior to the robotic construction and equipped with markers and tags. A camera on the end effector measures the tags for localizing the robot. For further information: In situ Fabricator

ABB robot arms IRB 4600 on linear axis IRBT 2005 Two industrial robot arms of the type ABB IRB 4600 are located below the balcony of the RFL and can be used to process projects with a working area up to 10 x 5 x 2.5 meters. They handle payloads of a maximum of 40 kilogramms. The modular design allows easily an extension of the linear axis to increase the work area. For further information: ABB IRB 4600

Image: KEYSTONE/Christian Beutler UR10 robot arms We have three robot arms of the type UR10, which are ideal for the automation of processes and tasks with a maximum payloads of 10 kilogramms. They are especially suitable for processes in which robot and humans cooperate in close proximity. Their working radius amounts to 1300 millimeters. For further information: Universal Robots UR10

UR5 robot arms Our six UR5 robot arms are used for research projects in the context of our MAS DFAB programme. They are suitable for tasks with a maximum payloads of 5 kilogramms and a maximum working radius of 850 millimeters. For further information: Universal Robots UR5

Zwick load testing device Our Zwick 1484 model is suitable for compression tests and has the following technical specifications: RetroLine tC II, Fmax 200 kN, test room width 630 mm, traverse stroke 2200 mm, test speed up to 200 mm/min. 3D Printer Two machines of the type BQ Hephestos 2 are available for 3D printing projects. Hephestos 2 is a fused deposition modeling (FDM) printer with a maximum resolution of 0.1 mm. Polylactic acid (PLA) and flexible filament can be printed. The maximum size of a printed element is 210 x 297 x 220 millimeters. Voxel Jet The VX1000 prints particle materials (sand) using a binder with a resolution up to 600 dpi. The assembly space measures 1000 x 600 x 500 millimeters. |

| Copyright 2024, Gramazio Kohler Research, ETH Zurich, Switzerland | ||

|

| ||

|

Gramazio Kohler Research

Chair of Architecture and Digital Fabrication ETH Zürich HIB E 43 Stefano-Franscini Platz 1 / CH-8093 Zurich +41 44 633 49 06 | Follow us on: Vimeo | Instagram | |